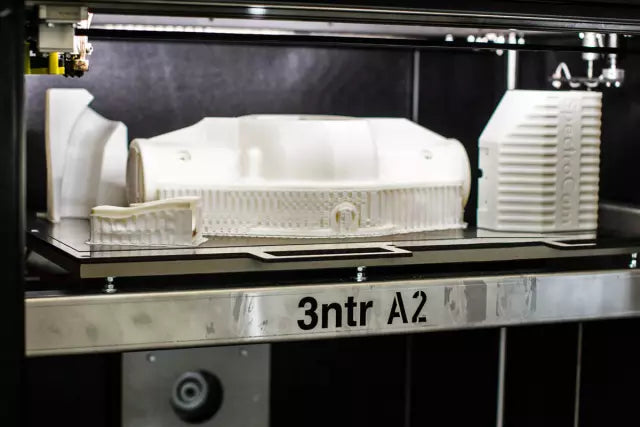

3ntr A2v4 / A4v4

OnAdditive carries the 3ntr 3D printer line, including the A2v4 and A4v4 multi-material printers, known for their industrial precision and reliability. We think you'll find that a 3ntr system can significantly enhance your company's prototyping, testing, and manufacturing workflows. Our open material library further expands the capabilities of 3ntr printers, allowing for a wide range of material uses and combinations.

See special deals below!

Download A2/A4 Spec SheetsSpecial deals on showroom printers

We're currently offering discounts on low hour showroom 3ntr 3D printers! These machines have been rigorously checked and are in like-new condition. They come with our standard support package and a one year warranty.

The 3ntr Family of printers are in companies of all sizes around the U.S. You can find them in companies from two person machine shops, to some of the largest companies and agencies in the country.

Interested in getting a 3ntr system in your workplace at the deepest discount we've ever offered? We'll provide in depth part cost analysis and even print your part for you to see if it meets your requirements. Contact sales@onadditive.com to learn more!

Contact Us Today!

A2v4 Technical Specifications:

- Print Volume:600x325x500mm / 24.6x12.8x19.7in, suitable for large-scale parts and high-volume batches.

- Triple Nozzle Print Head: Enables multi-material/color printing without filament change mid-print.

- Water Cooled Print Head: Maximum nozzle temperature of 350°C, extendable to 450°C with VHT add-on.

- Open Material Library: Print with any material, anytime. KISSlicer profiles for OnAdditives materials provided.

- Core XY Movement: Fast and precise printing, with 11 micron XY precision and 40 micron Z precision.

- Chamber and Build Plate Temperature: Chamber temp up to 90°C, build plate temp up to 125°C.

- Power Requirement: Available in 220V 15amp with a custom cable fitting to match your needs.

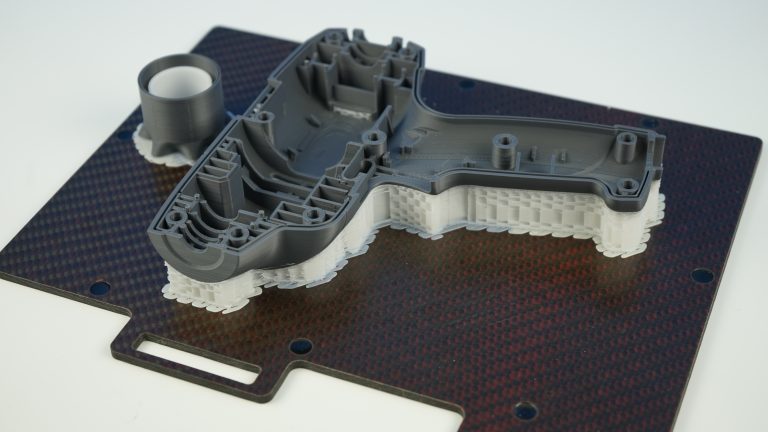

Carbon Fiber Ultem Coated Print Bed

Both the A2 and A4 printers (A4 size shown) come with a carbon fiber ultem print bed, often refered to as the diamond print bed because of it's pattern. This ultem coating means amazing adhesion at temperature, then automatic print release when cooled down!

A4v4 Technical Specifications:

- Print Volume: 300 x 171 x 200mm / 12 x 6.75 x 7.9in, ideal for low volume production and smaller parts.

- Triple Nozzle Print Head: Enables multi-material/color printing without filament change mid-print.

- Water Cooled Print Head: Maximum nozzle temperature of 350°C, extendable to 450°C with VHT add-on.

- Open Material Library: Print with any material, anytime. KISSlicer profiles for OnAdditives materials provided.

- Core XY Movement: Fast and precise printing, with 11 micron XY precision and 40 micron Z precision.

- Chamber and Build Plate Temperature: Chamber temp up to 90°C, build plate temp up to 125°C.

- Power Options: Available in 110V 5amp or 220V 3amp configurations.

Note: The A2 and A4 models share almost all specifications, with the primary differences being build size and power requirements.

Download A2 & A4 Spec SheetThe 3 Nozzle Advantage

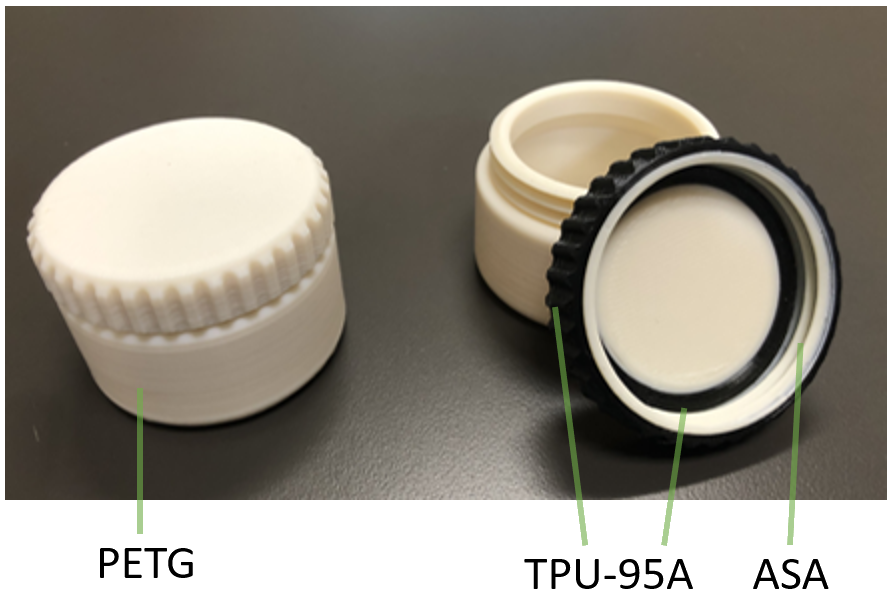

Unparalleled flexibility and robustness. 3ntr 3D printing technology harnessed by OnAdditive takes flexibility and robustness to new heights. By combining different polymers, you can create parts with enhanced efficiency and functionality. For instance, integrate built-in, water-tight seals using TPU 95A directly into materials like ASA, PETG, PA12 and beyond. This capability not only streamlines the manufacturing process but also opens up innovative possibilities for more complex and effective part designs. Experience the power of seamless integration and material versatility with OnAdditive.

Read more

Material Management System (MMS)

- Electronic Filament Monitoring: Monitors up to 6 spools with electronic scales and live readout.

- Heated Material Storage: Environment up to 40°C, holds 10 spools + 6 on scales for warm, dry storage.

- Air Filtration System: Built-in HEPA and charcoal filters, plug and play compatible with 3ntr A2/A4 for air filtration.

- Humidity Control: Large reusable desiccant, with live humidity display on the front panel.

- Print Server: Includes solid state server for MMS and 3ntr system integration, enables 24/7 printing with remote monitoring and control.

- Design Compatibility: Specifically built to support 3ntr A2 and A4 printer systems.

Additional Accessories:

How can a 3ntr 3D Printer Augment your Workflow?

Whether you're a a full time machine shop looking to expand your capabilities, an R&D wanting to experiment with additive manufacturing, or even a a company providing final end use parts, we're confident a 3ntr 3D printer will help you reach above and beyond your goals.

A Week in the Life of an A2 Industrial 3D Printer